The dimensions of the construction industry have taken a paradigm shift over the last few decades. And among the different modern innovations, the concept of Pre-engineered Buildings (PEBs) is something that stands apart. The e-commerce and online retail industry have become a contributing factor in the popularity of PEBs. And due to the growing needs for additional storage space, businesses have started looking for the most experienced fabricators in Odisha.

Now, before discussing its benefits, let’s get to know more about the concept of PEB.

What is a pre-engineered building?

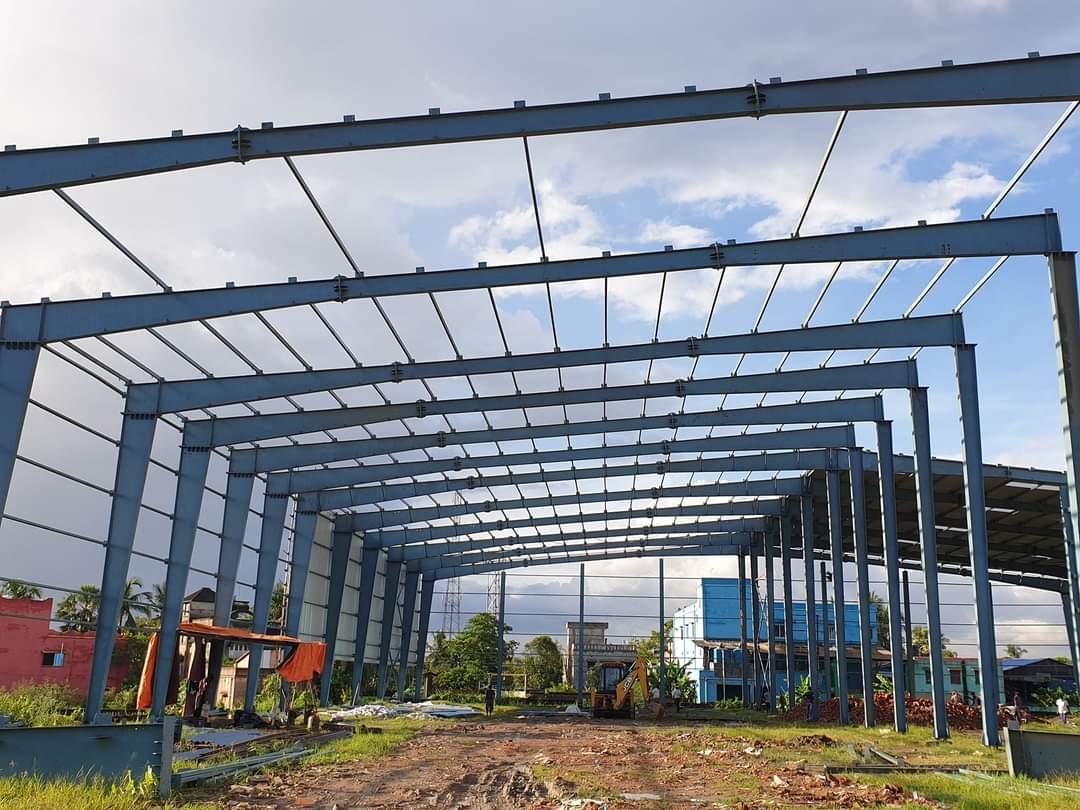

A pre-engineered building is a framework or structure developed by the manufacturer. It is created using an inventory of fabrications and materials which are previously agreed upon. Being different from conventional buildings, it can come with a host of custom-built features and unique architecture. What makes it a superior option is it can be designed in comparatively lesser time and by incurring reduced costs.

Find out some of the most rewarding benefits of PEBs.

Offer a variety of architectural options

Customers or architects can select from a host of wall panels in terms of design. Depending on their unique requirements, they can even consider customizing the structure to make it look attractive and more functional.

Highly durable structures

PEBs are pre-fabricated by following a list of guidelines in a controlled setup. This makes it stronger and highly durable enough to deliver a quality-oriented performance. The pre-engineered roofs are observed to last longer than other conventional roofs.

Require low maintenance

PEB structures are designed to last longer and don’t need extensive maintenance. Steel is resistant to rust and corrosion. And this is why these structures are maintenance-free compared to conventional buildings.

PEBs are a modern solution designed to cope with the evolving trends and industry patterns of the construction sector. And this is why you should look for renowned fabricators who successfully handled similar projects in the past.

At Unitech Structural Works, we have more than 20 years of experience handling a vast range of bridge fabrication and structural steel fabrication projects. We offer all types of appropriate equipment, complete installation, comprehensive assembling, as well as project management. We are specialized in designing, manufacturing, transporting, engineering, and on-site installation. So, contact our experts now for any kind of assistance in the genre of pre-engineered steel building structures.