Our Services

Step 1

Initial Planning & Proposals

Preliminary discussion relating to the need of the client is understood and a basic project planning is done to determine few key details of a Pre-engineered Steel Building like length, width, height, etc. We guide our client towards the most optimized ways for constructing an Industrial building. Following this we generate estimation and proposal drawings for a precise understanding of the upcoming steel building.

Step 2

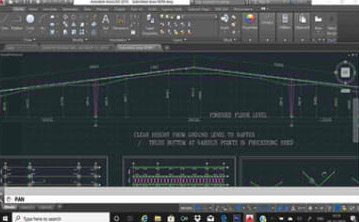

Design & engineering

Upon finalization of the contract we move to the next step of building engineering which involves design & detailing of the steel building as per latest design codes and generates shop drawings. Our primary aim while designing a steel building is to make it sturdy & safe considering all the safety factors without any compromise on steel consumption.

Step 3

Manufacturing

Once detailed shop drawings are ready, then we move on to the next process of Manufacturing / Fabrication process at our Kolkata-WB Plant or at Client’s site as per the construction model selected in step 1. The complete process of manufacturing includes processes like fabrication and surface coating with atleast 3 coats of paint. All the pre-engineered parts are made for ready-to-assemble & instant installation at site.

Step 4

Logistics

Following the completion of manufacturing & coating process, every single item is once again cross-checked for quality assurance purpose and then loaded on a suitable vehicle as per road and project conditions. The entire loading and handling process is carried on via suitable hydraulic service crane for a very quick loading & dispatch time.

Step 5

on-site assembly & structural installation

Upon receipt of PRE-ENGINEERED FABRICATED PARTS at project site, we start with the process of assembly with high tensile bolts & nuts. Once the assembly of the parts are done we then start the erection & alignment process at site via Mechanical or Hydraulic high range Cranes with complete supervision and safety. Our group of teams are very skilled and competent to erect and align the structure at a very fast pace of 5-15MT of structural erection in a single day. As per our design all the parts are manufactured in such a way that assembly & erection time is highly optimized & planned for maximum time efficiency.

Step 6

roof ppgl/insulated sheet installation

Once the entire main frame and secondary members is erected and installed then we start with the final process of installing Pre-painted Galvalume Metal Sheets with Galvanised Self Drilling Screws. We take additional care to carry on this task with utmost precision & appropriate finishing. Since the whole building is designed & manufactured as a single system approach we also install other typical PEB accessories like rain water gutter, down take pipes, corner flashing, gable barge flashing, drip trim, translucent day light sheets and finally turbo ventilators in case of air exhaust management.