Sustainable development and green buildings are common terms in the construction industry. When compared to conventional buildings, the PEB structures are eco-friendly. The engineers fabricate them with careful attention. They assemble the components at factories as per the project details. Then they assemble and erect it at the site after transporting it safely.

You can consult the professionals for pre-engineered building in Jharkhand to meet your structural needs. The PEB buildings allow multiple configurations and custom designing. Further, its environment friendly nature makes it a preferred choice for all.

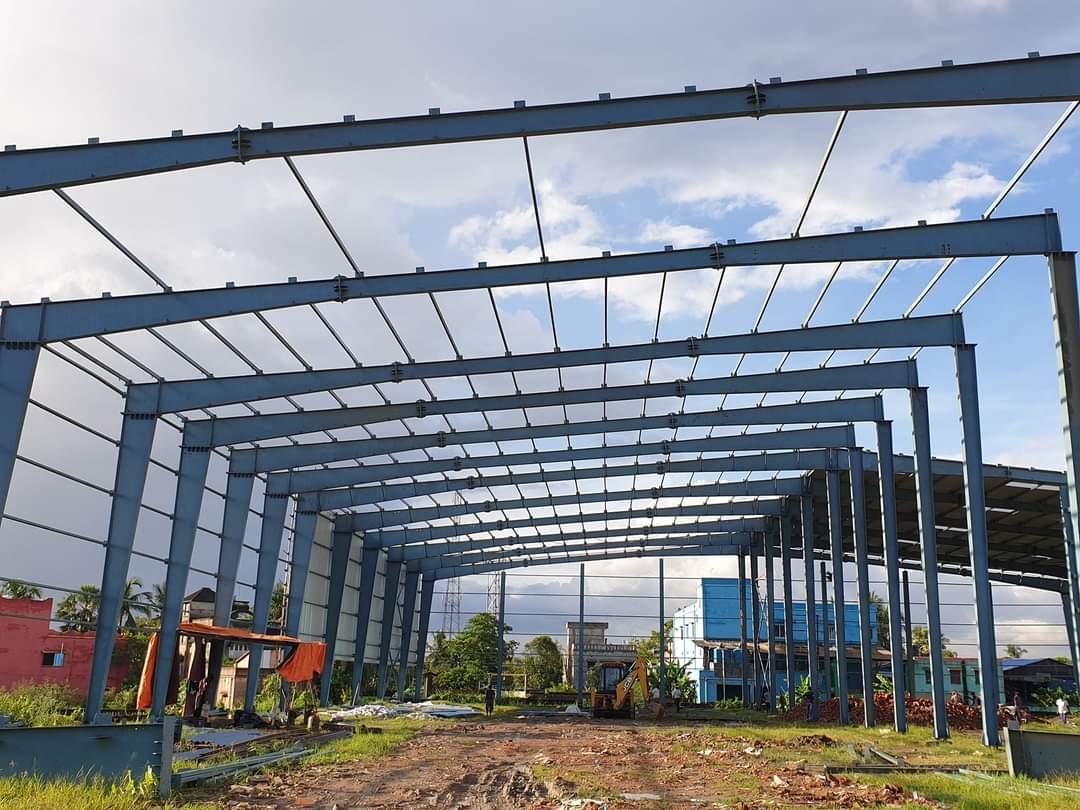

The PEB Structure Components

You can classify the components of the Pre-engineered buildings into several categories.

- Primary built-up members like framing parts

- 1. Rafters

- 2. Columns

- 3. Z Purlin, cold and hot-formed roof purlins

- 4. C Purlin and hollow section

- 5. Roofing Sheet and cladding

- 6. Eave Struts

- 7. Bracing

Are PEB Structures Eco Friendly?

- 100% Recyclable

Steel is easy to recycle than any other material. This is because steel separates from the other waste matter by using electromagnets. You can recycle the steel multiple times according to your necessity. Yet, it does not lose its original strength and tenacity. The manufacturers use recycled steel to make new steel. It reduces the cost of building construction and save the environment. This is why Pre-engineered buildings are the best replacement for any other structure.

- Save Landfill

The fabricator uses recycled steel to make PEB structures. The buildings are stronger and have an increased lifespan than other structures. They reduce the amount of waste matter/rubbish thrown into the landfills. Buildings made in traditional methods of construction generate more waste. All this rubbish is non-recyclable. The steel structures do not go into landfills. The technicians recycle the steel without producing any waste.

- Energy Saving

The PEB buildings are energy efficient. They drastically lower the electric bills. By installing wooden door frames, you are likely to suffer from problems like air leak and moisture. It is not the same with Pre-engineered buildings. The steel elements retain indoor temperature and save electric bills. Hence, it creates no pollution.

Meet the Reliable PEB Fabricators

Unitech Structural Works is a reputable company working with a team of experienced PEB fabricators. You can get high quality, bespoke PEB structures from manufacturers at competitive prices. We ensure the flawless design and engineering for 100% client satisfaction.