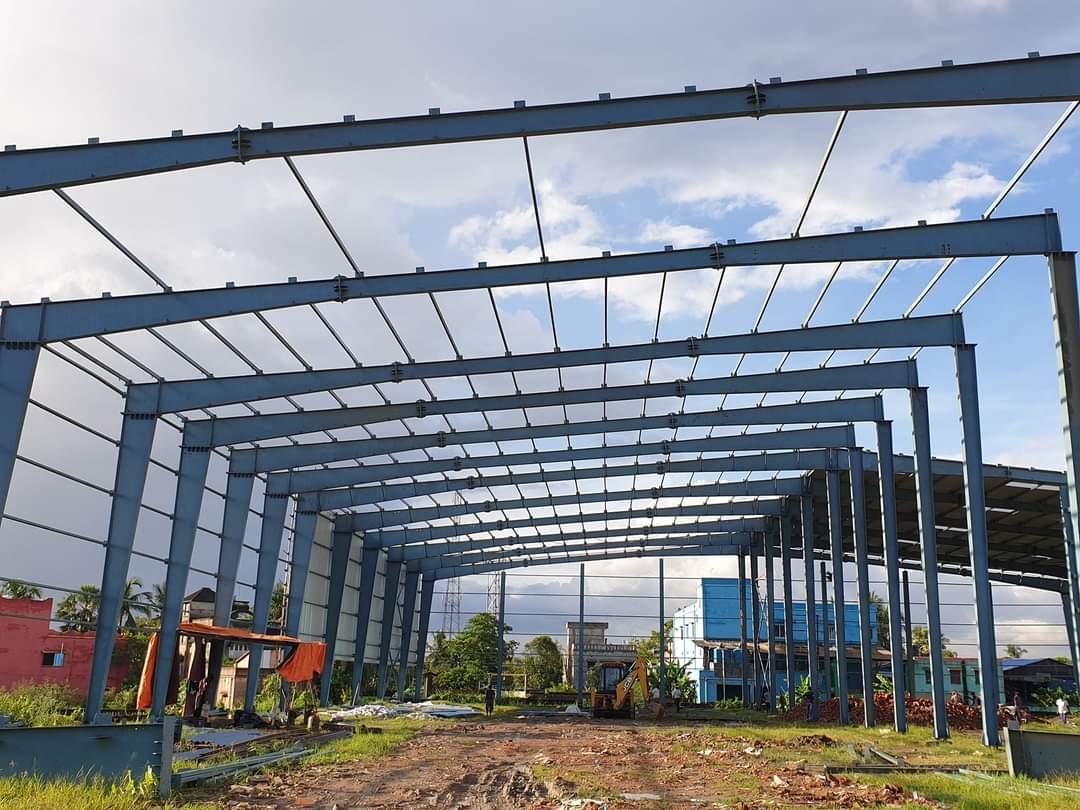

Different construction agencies are opting to construct an establishment in a quick time. However, they also have to take cognizance of the safety norms, utilities and other important features. They have found a useful alternative in Pre Engineered Building.

The Demand of Pre Engineered Building

PEB is much popular among industrial steel fabricators. It saves the extra labour, the cost and most importantly, time. From establishing residential to commercial spaces, the traditional way of construction is slowly taking a backseat.

The main element of a building is its base. However, industrial fabrication shuns the process of digging the ground to establish a foundation. The whole construction is held by metal beams that are placed on a concrete surface.

Why is Industrial Fabrication a Practical Option?

There are also some practical reasons why PEB is a favourite among the industrial fabricators in Assam.

- Flexibility: The construction work on PEB can be an extremely flexible option. One can execute multiple types of construction with steel beams. The on-site execution and customization are simple too.

- Easier Transit: The on-site construction needs a large number of steel products. Unlike traditional construction methods, these can be transported easily, unlike brick, mortar and concrete.

- It is sustainable: The PEB construction is done with durable metals like stainless steel, which is why it is much more sustainable. The construction would not need a large dispatch of concrete products, which can cause pollution.

- It is cost-effective: This is the most practical reason why people choose Industrial fabrication. The labour cost is reduced, and the completed construction is generally delivered on time. There are also fewer possibilities of pushing back the dates.

- Minimal Designing: The brick and mortar construction needs considerable attention on the design. However, due to the usage of lightweight and convenient items, the design of the house becomes sleek. The assembling process is also quicker.

Know About Unitech Structural Works:

For better assistance in industrial fabrication constructions in Assam, one can take the help of Unitech Structural Works. They are an experienced name in this field who can provide the best professionals and finest construction materials. The process of building and handover time is also gets reduced.

The points discussed above are some of the reasons why construction agencies and clients choose PEB construction. Compared to the traditional methods, it is a fast and much more flexible option.